Keeping as much as possible in-house allows for greater control.

The machine shop at SpecJ is the core of our business. We pride ourselves on our state-of-the-art facilities and modern techniques, allowing us to work to the tightest tolerances to provide the best product for the end user. See below for examples of some of the services we offer:

Jump to section

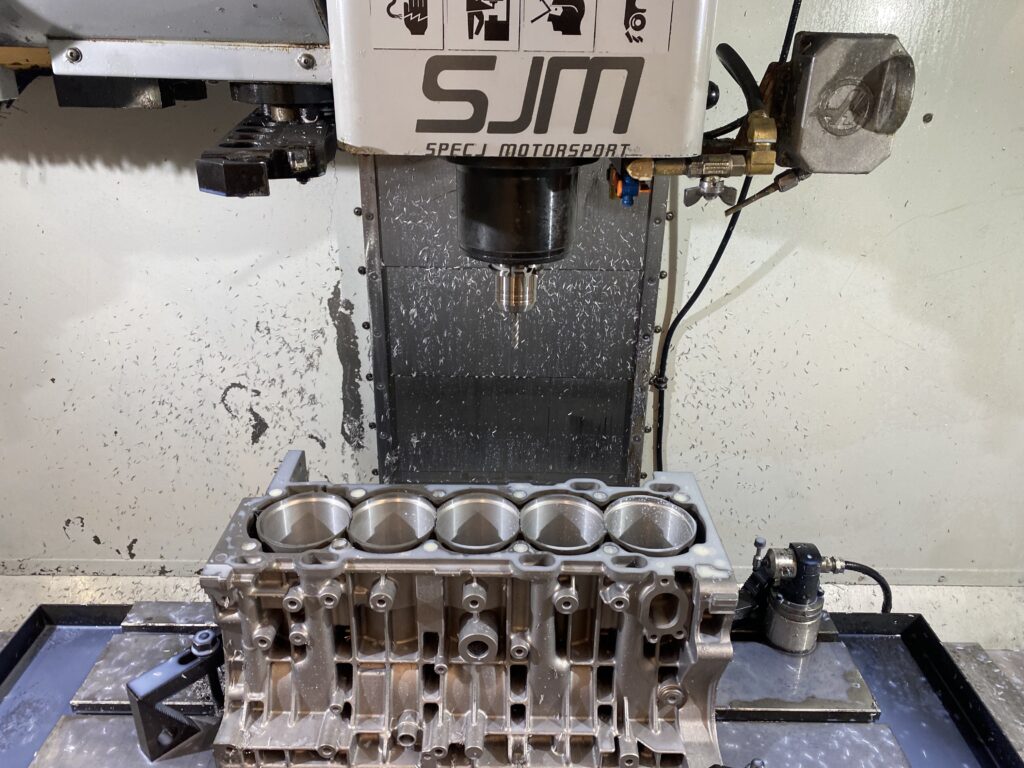

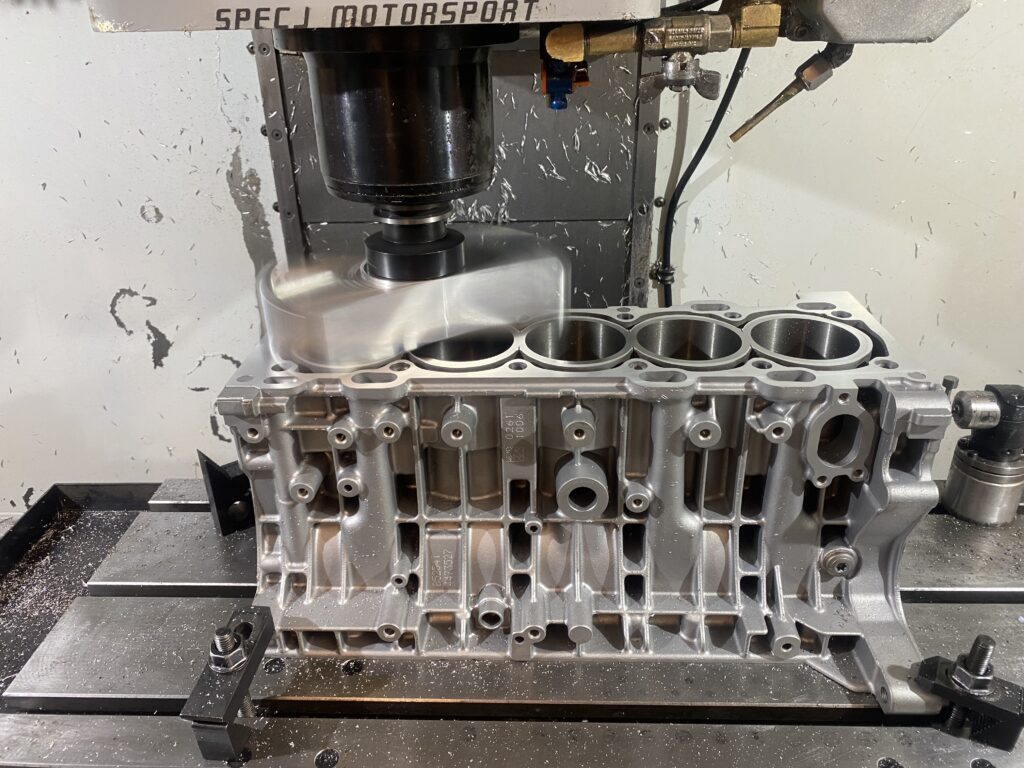

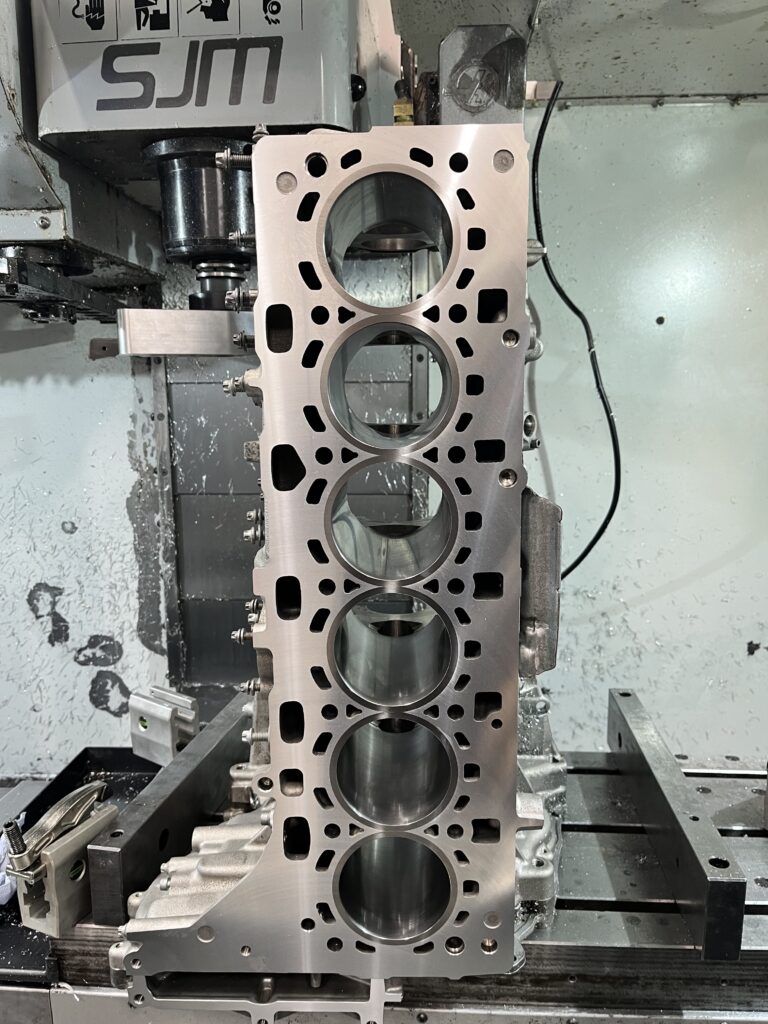

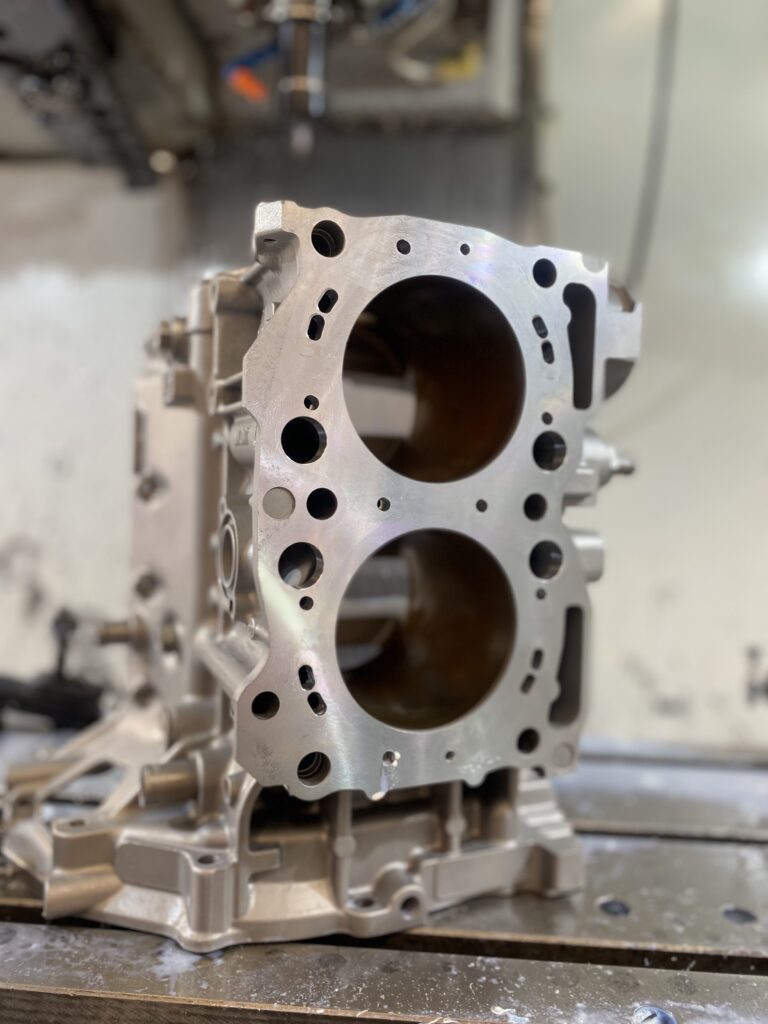

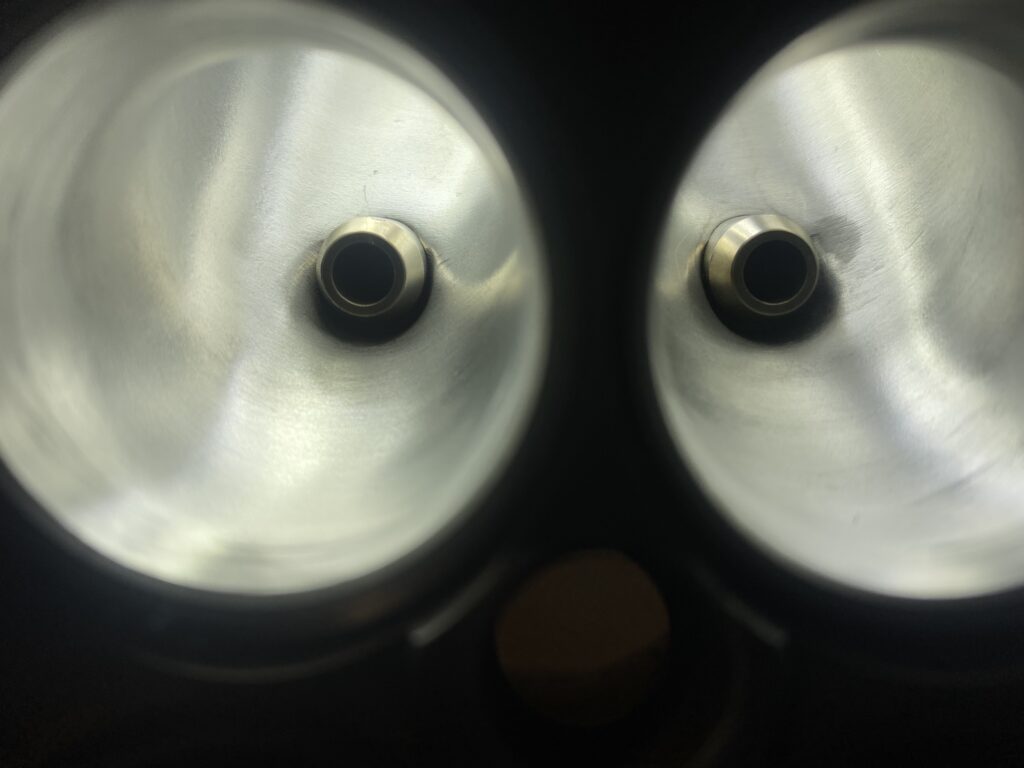

Cylinder boring and torque plate honing

Using our HAAS VMC, we are able to accurately bore any cylinder block, including ‘V’ style engines, using our rollover fixture. Boring on the VMC allows us to set the correct bore spacing, alignment to the crankshaft tunnel and offset bore a cylinder if need be with ease.

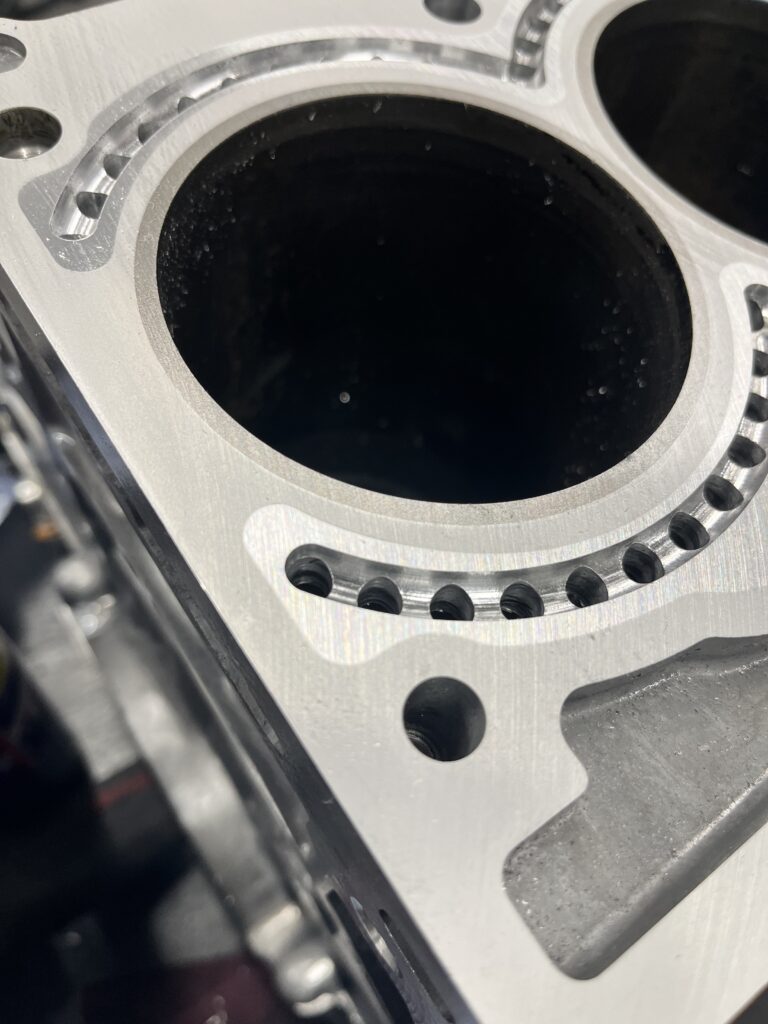

When it comes to honing, we understand this is a science. Known as ‘Extreme Plateau Finishing’, a 2 step process takes place during honing, a rough diamond abrasive to set the valley depth for oil retention followed by a fine grit diamond or CBN abrasive with a lower stone pressure to flatten the peaks, giving the rings a smoother surface to seat against. Our Rottler diamond cylinder honing machine is one of the best on the market today, producing extremely accurate results when it comes to ovality and taper. Using diamond abrasives alongside our Mitutoyo SJ-210 surface profilometer allows us to dial in the surface finish of the cylinder to suit the given application, giving fast break-in, superior ring seal and longevity of your engine! Using a torque plate (where applicable), along with the same gasket and head studs/bolts used for your build, simulates as close as possible the built conditions of the engine, allowing a much straighter cylinder once assembled.

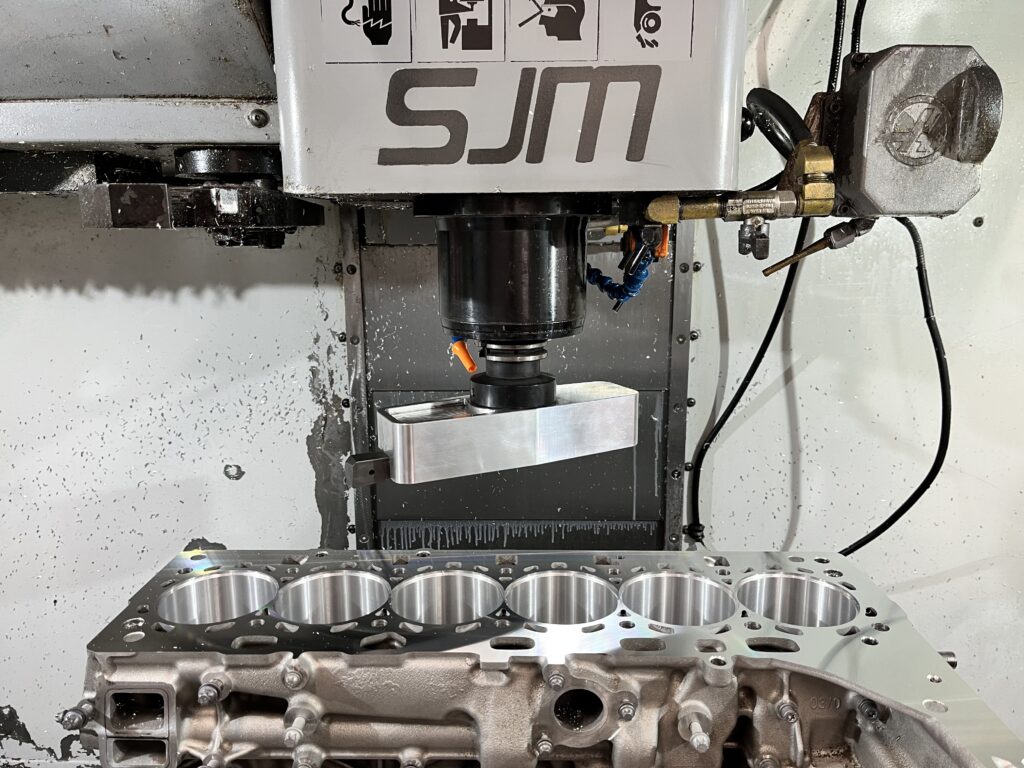

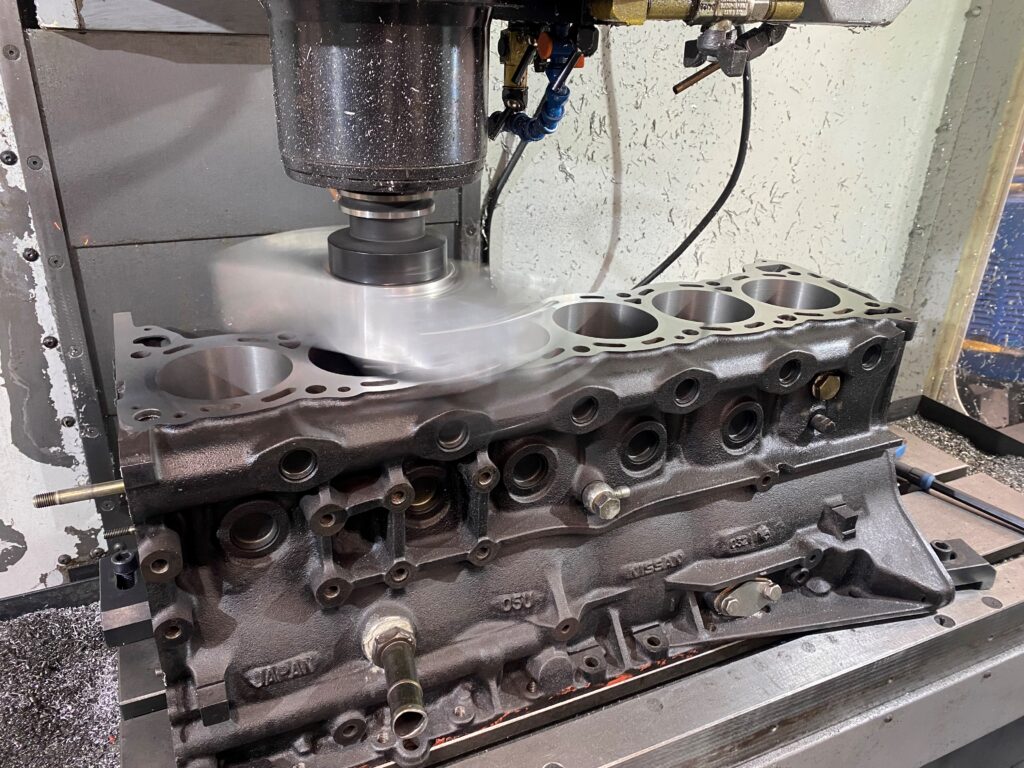

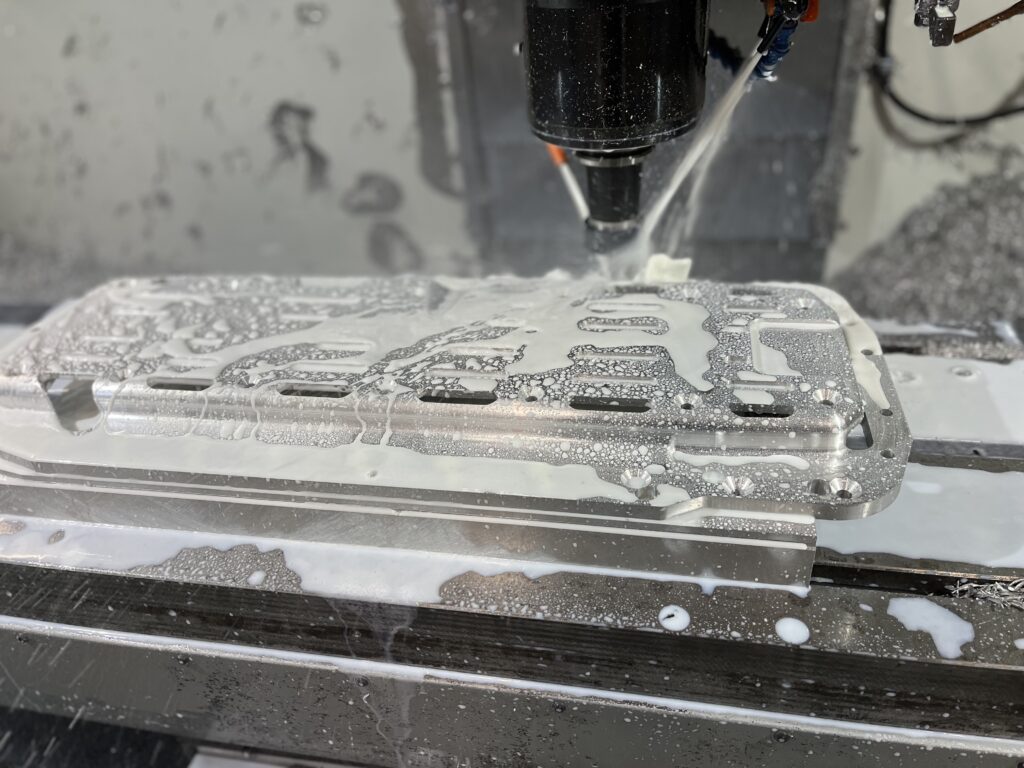

Cylinder Head Surfacing/Cylinder Block Decking

Surface milling on the machining centre allows very accurate cuts to be taken, allowing us to take the minimum to simply refresh the surface, or to remove an exact amount to set the deck height. A PCD (Polycrystalline Diamond) cutting insert is used to surface mill aluminium cylinder heads and cylinder blocks, and a CBN (Cubic Boron Nitride) insert for cast iron cylinder blocks. Using these types of cutters allows for a much finer surface finish over conventional methods, meeting the RA finishes required for todays MLS head gaskets. All finishes are verified with our Mitutoyo SJ-210 profilometer.

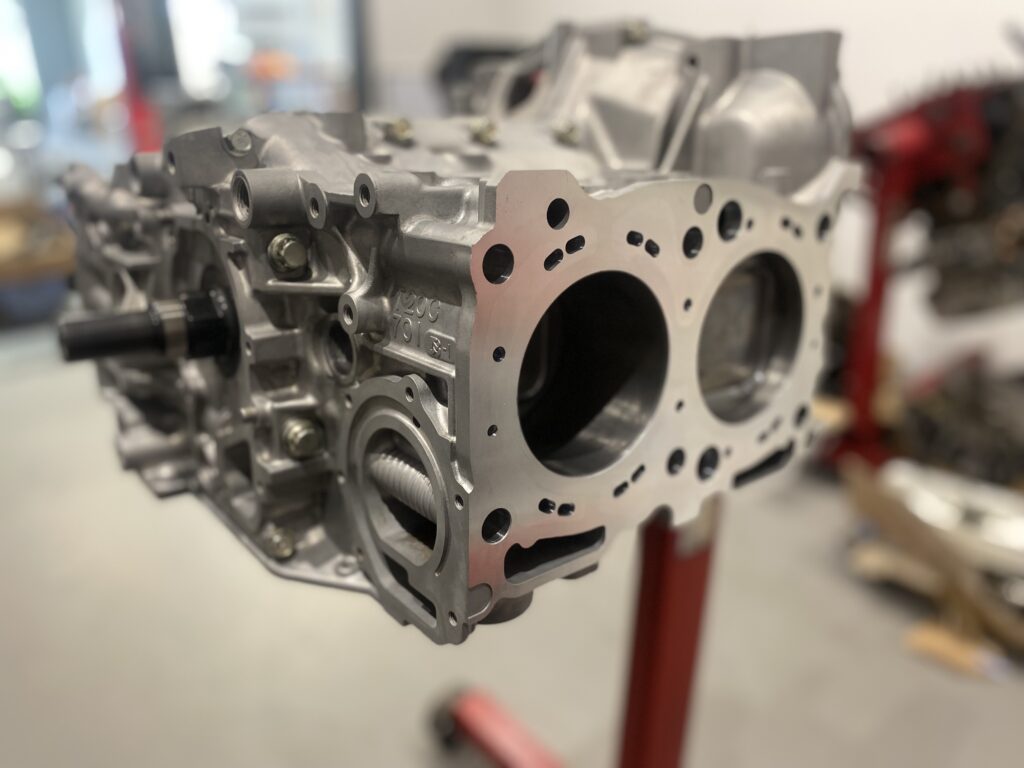

Cylinder Block Sleeving

We specialize in cylinder block sleeving, in particular aluminium blocks. We are fully equipped to carry out this very precise, time consuming job and can supply and install both wet and dry liners from major manufacturers such as Darton, LA Sleeve and Westwood Cylinder Liners. Some of the main cylinder blocks we sleeve are:

- BMW B58 (Manufactured exclusively for us by Westwood Cylinder Liners)

- BMW N54/N55/S55

- FORD 5 CYLINDER RS/ST

- HONDA B SERIES

- HONDA K SERIES

- AUDI DAZA

- NISSAN RB26

- NISSAN VR38

Benefits of Ductile iron sleeves from a performance point of view:

- Improved block integral strength

- Improved ring sealing and ring wear

- Superior oil and and compression control

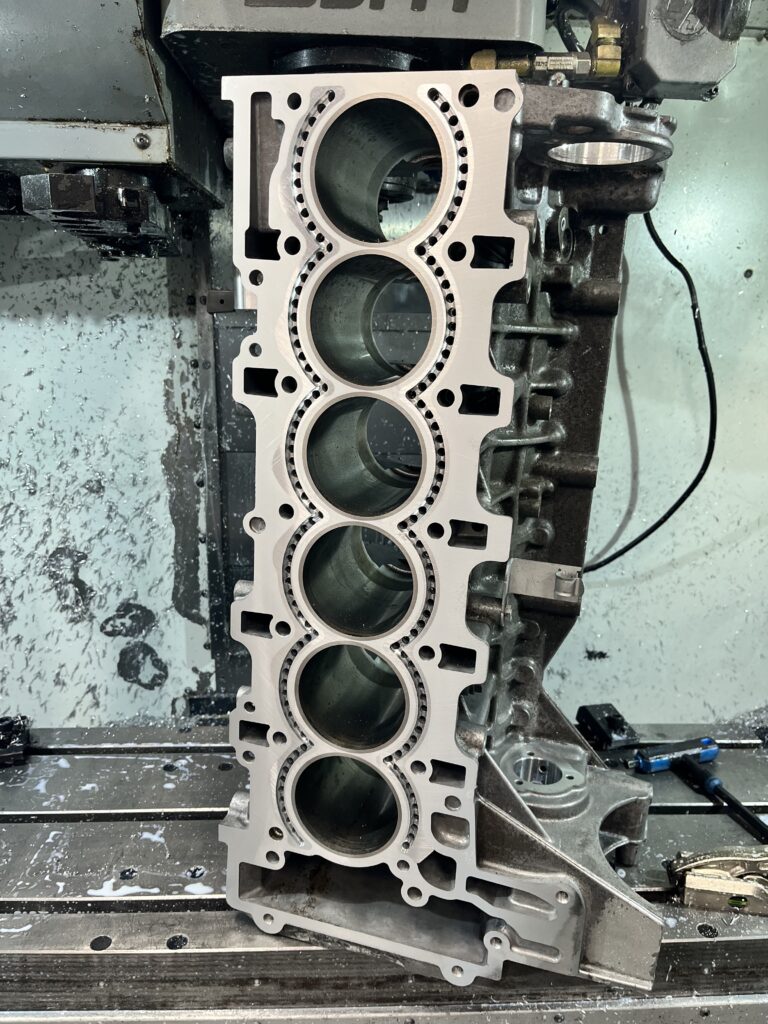

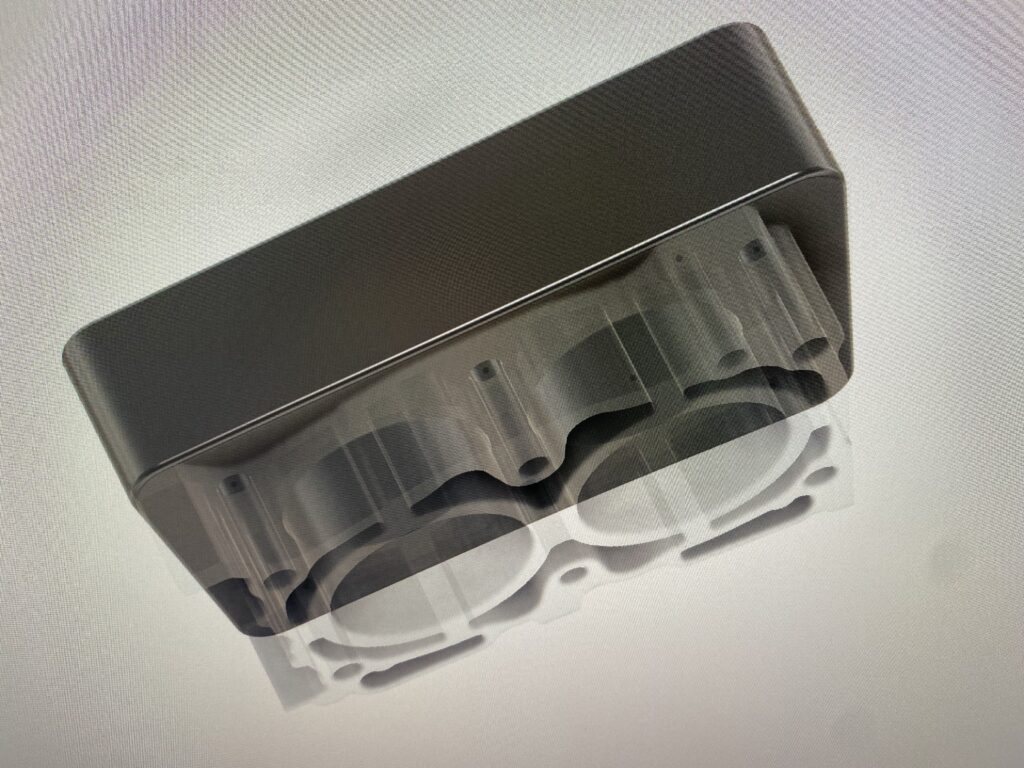

Closed Deck Modifications

Closed-deck blocks not only offer a more robust engine, but an increased clamping surface, more structural rigidity, better engine harmonics and raised capacity for elevated cylinder pressures. This results in a more reliable engine at higher boost when compared to the original open deck blocks.

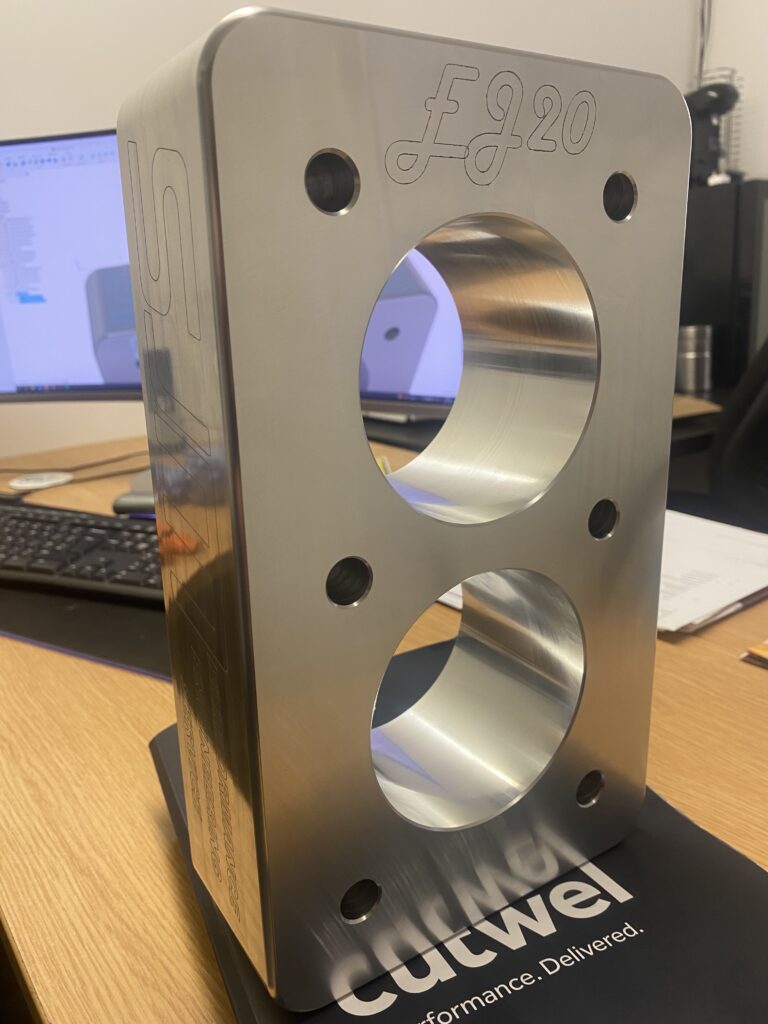

Custom Made Parts

We already make a range of parts for Nissan, BMW, Mitsubishi and many more. Whether you supply us with a CAD model or just a problem that needs solving we are happy to help.

From initial idea down to the finished product. All modelling and machining will be done in house.

Cylinder Head Porting

Porting of cylinder heads is often needed to improve an engines characteristics. This is accomplished through modification to the intake and exhaust ports but is not limited to the cylinder head. We would normally have a conversation with you about what your expectations are for the engine and then discuss what other modifications are needed to achieve your goals. We are here to help, so give us a call and have a chat.

Valve Seats & Guides

From manufacturing custom valve guides to replacing the valve seat inserts, as part of a fully flowed cylinder head, or just a repair on worn out guides. We have the knowledge and skills to carry out the task in hand and we pride ourselves on doing the best job possible.